What do you know about cavitation and how it affects the operation of a water pump?

The word cavitation comes from the Latin cavus, which means hollow space. At a technical level it is defined as the rapid formation and collapse of cavities in areas of very low pressure in a liquid flow.

The fundamental physical condition for the appearance of cavitation is that the pressure at the point of formation of these cavities decreases up to the vapour pressure of the fluid in question.

Cavitation is a common phenomenon in hydraulics, it affects the operation of centrifugal pumps, decreases the performance of the installation, it presents noise and vibrations that directly influence maintenance costs.

Some of the actors involved in cavitation are related to

- The fluid, such as: temperature, density, physical-mechanical properties, chemical composition.

- The characteristics of the network: suction height, atmospheric pressure, suction losses

- The pump: flow rate and rotation speed

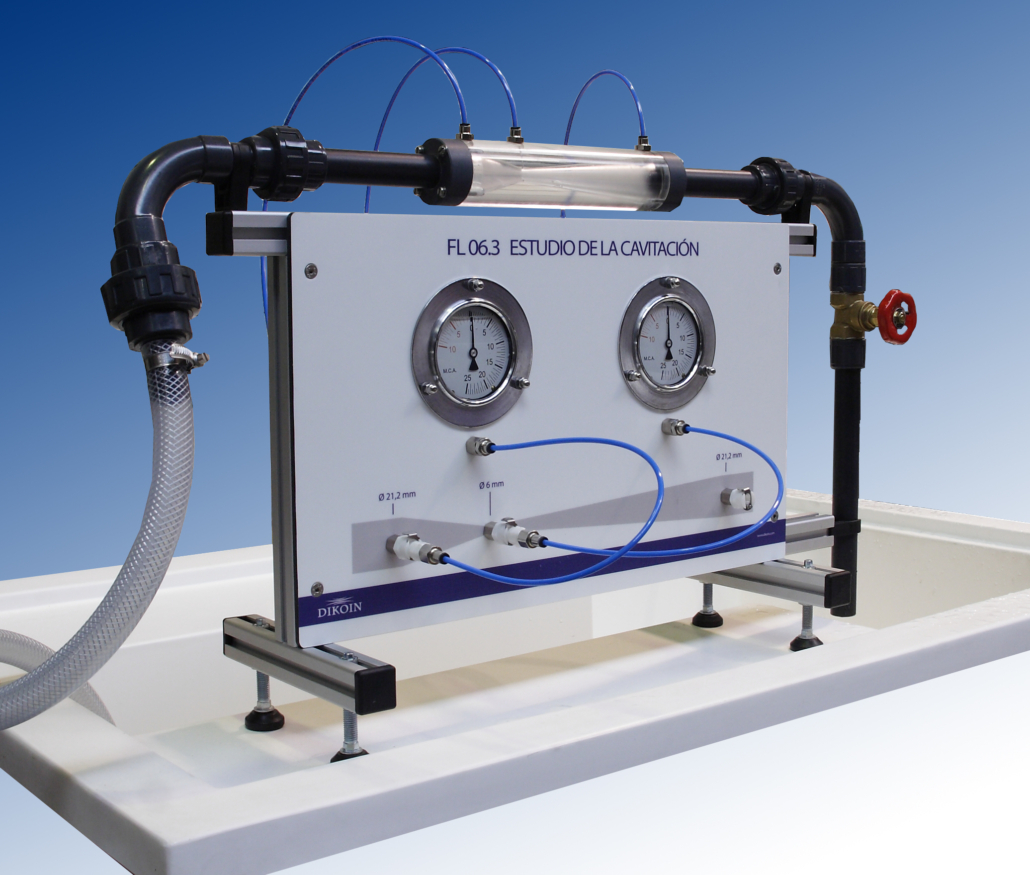

To study this phenomenon, Dikoin proposes the following equipment to carry out very interesting laboratory practices due to their simplicity for teaching and researching the fundamental aspects of the phenomenon.

It consists of a venturi tube in whose throat the phenomenon of cavitation occurs due to the depression created in it by the acceleration of the flow (Venturi effect). For a correct observation of the phenomenon, the methacrylate’s Venturi has been built The equipment also has two manovacuometers with which we can measure the overpressures and depressions produced. For the regulation of the flow, a regulation valve is used that allows a fine adjustment of it.

FL 06.1 Venturi, Bernoulli and Cavitation effects

Whose objectives that are intended to be achieved with the realization of the practices with this equipment, are both the study of the venturi effect from its initial theoretical conception, Bernoulli’s theorem, and the observation and use of some of its practical applications; applications that we can find in fields as diverse as industry, agriculture, leisure, etc. as well as the study and observation of cavitation, it is also possible to change the pressure conditions in the suction tank, with which we can study the phenomenon for different flows and pressures.

Título MH 05.1 Visualization NPSH

It has been designed to visualize the phenomenon of cavitation that occurs when the pressure of the liquid we are pumping decreases to its vapor pressure for the operating temperature. At that time, the liquid vaporizes, forming cavities or pockets of vapor that are drawn into areas with a higher pressure where they condense again, generating very high point overpressures.

The most direct consequences of the phenomenon described above are strong vibrations in the machine, oxidation, detachment of the material and a decrease in both the manometric height and performance.

The stroboscope arranged, and adjusted in frequency to the speed of rotation of the pump, makes us see the impeller “stopped”, so that the visualization of the phenomenon is unbeatable.