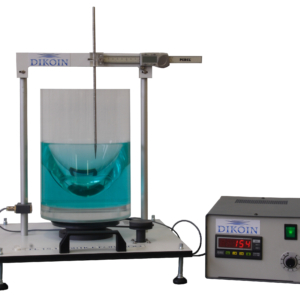

FL 06.1 – Venturi, Bernoulli and Cavitation Effects

The objectives to be achieved with the learning of the objectives with this equipment are the study of the venturi effect from its initial theoretical conception, the Bernoulli’s theorem, and the observation and use of some of its practical applications; applications that we can find in diverse fields as industry, agriculture, leisure, etc.

Another objective to be covered is the study and observation of the phenomenon of cavitation, and it is also possible to change the pressure conditions in the aspiration tank, so that we can study the phenomenon for different flow rates and pressures.

The user manual clearly shows and with a large number of images, the entire process to be followed to operate the equipment. The practical manual shows and explains all the theoretical foundations, as well as the mathematical formulas used for the realization of all the experimentation.

Together with the user manual, a completely resolved manual is given with the data to be obtained during the practice with the equipment. In this way, the teacher can easily check if the students are doing the job correctly.

The experiments to be carried out with this equipment are the following:

Demonstration of Bernoulli’s Theorem along a venturi tube.

Calculation of the head loss of a venturi tube.

Use of the static volumetric system for the determination of flows.

Taring and use of a diaphragm to know the flow rate.

Observation and use of practical applications of Venturi effect such as:

- Use as a suction pump for mixing liquids; Industrial applications, addition of fertilizers for irrigation, etc.

- Use for mixing water and air; hydromassage, etc.

- Taring and use of the venturi tube as a flow meter.

Study of the cavitation, knowing the pressure and temperature at which it is produced and the circulation flow.

Reduction of the internal pressure of the tank observing the new conditions necessary to obtain the phenomenon of cavitation.

- Main pipe:

- Øinterior = 21,2 mm.

- Øexterior = 25 mm.

- All connections are fast and double sealing

- 6 column multiple manometer water column, measuring range 0,6 m c.a.

- Electronic differential pressure manometer (±7.000 mbar)

- Bourdon type manometer, reading range 0 / 25 m c.a.

- Bourdon type vacuum gauge, reading range -76 cm Hg / 25 m c.a.

- Maximum manometric height 24 m.c.a.

- Flow: 20 / 120 l/min.

- Manometric height: 23 / 12 m.c.a.

- Consumed power 0,55 kW (0,75 HP).

- Turning speed 2900 r.p.m. (50 Hz).

- Power supply: 230V/50Hz.