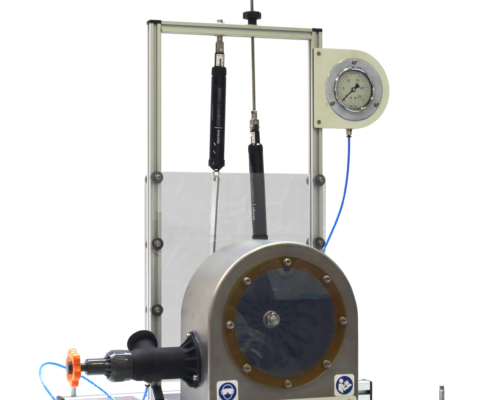

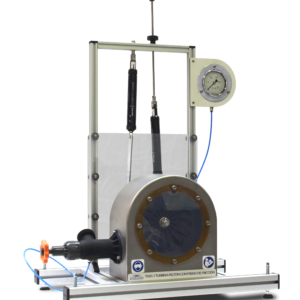

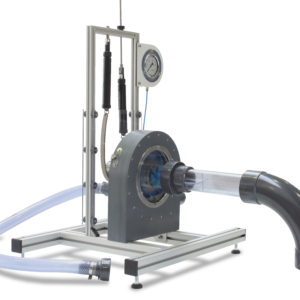

TH 01.1 – Friction Brake Pelton Turbine

The TH.01.1 equipment simulates an instalation in a small scale with a Pelton turbine. It has been designed with special emphasis on the didactic aspect of the same, being able to observe at all times the operation of the system and the different components that constitute it.