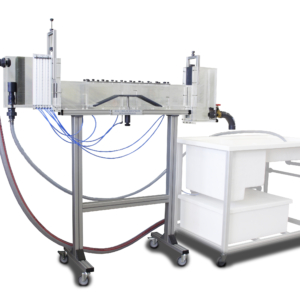

TA 02.2 – Sedimentation Tank

This equipment enables the continuous study and visualization of the natural sedimentation process, in which particles denser than the fluid in which they are dispersed settle to the bottom of the container due to gravity.

Description

Sedimentation is used to clarify various types of water by reducing turbidity. Depending on the characteristics of the suspension, particles settle differently according to their density, concentration within the mixture, and the density and viscosity of the dispersing fluid.

The sedimentation tank includes a lower mixing reservoir where the suspension is prepared by adding the additive to be studied. This reservoir is equipped with an agitation system designed to prevent premature sedimentation of the suspension.

Learning Objectives

- Study of the basic principle of separation of solids in suspensions by sedimentation tanks.

- View and study the sedimentation process in a continuous sedimentation tank.

- Determination of the efficiency of the sedimentation process for:

- different concentrations of solids.

- different flows.

- different positions of the deflector plate.

- different depths of the deflector plate.

- Visualization and study of current lines for:

- different concentrations of solids.

- different flows.

- different positions of the deflector plate.

- different depths of the deflector plate.

Technical Data

Sedimentation tank:

- Construction material: Transparent methacrylate.

- Approximate capacity: 80l.

- Dimensions: 1000 x 400 x 200 mm.

Suspension tank:

- Construction material: Fiberglass.

- Approximate capacity: 120l.

- Continuous mixing system.

Other characteristics:

- Anodised aluminium structure.

- Flow control through pressure control system.

- Recirculation pump. H= 32 / 14 m wc.; Q= 0 / 150 l/min; P= 0,75 kW. Special for operation with dirty water.

- 2x Imhoff cones, capacity 1 l. A wiper blade is included.

- 1x beakers 1 l.

- 1x precipitate jar 2l.

- Ink dosing system for improved visualization of the phenomenon.

- Includes a shovel for pouring of suspension material to the tank.

Requirements

- Power supply: 230V/50Hz.

- Running water intake.

- Calcium carbonate is required for the practice.