FL 03.1i – Computerized Series and Parallel Pumps

With this equipment you can practice much of the operations, start-up, operation and necessary regulations in a pump installation.

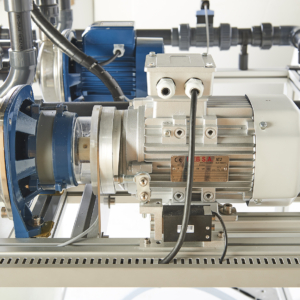

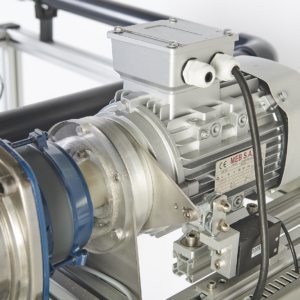

The two pumps that the equipment has are controlled by a frecuency variator, which allows varying the speed of rotation. One of the pumps has a mechanical torque measurement system.

The flow rate of each pump is measured by an electronic flow meter.

In addition, you can make an study of the characteristics of a pump, working individually and in groups, in series or in parallel, performing a wide range of practices and experiences.

The whole system is controlled by a computer with touch screen (included), from where the pumps can be swiched on or off, or change the turning direction of one (the one which has the torque measurement system).

Moreover, the software allows the recording of data manual or automatically, and show the results into graphs.

- Start-up of a pump, analysis and study of different aspects to consider.

- Priming pump.

- Checking the sense of rotation.

- Overcurrent produced in the engine.

- Study and obtain the characteristic curves of a pump.

- Height – flow (H-Q).

- Hydraulic power – flow (P-Q).

- Torque – flow (M-Q).

- Mechanical efficiency – flow (hm-Q).

- Mechanical power – flow (Pm – Q).

- Efficiency of the engine – flow (he-Q).

- Electric power – flow (Pe-Q).

- Total efficiency – flow (h-Q).

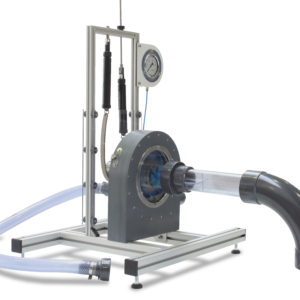

- Study of cavitation, and obtaining the N.P.S.H. Curve required-flow.

- Study of the different forms of regulating a pump. Checking similarity laws.

- Variation of the rotational speed. Obtaining the new characteristic curves.

- Changing the operating point by varying the pumping installation.

- Manoeuvred of the discharge valve.

- Analysis of the same and different pumps working in group.

- Characteristic curves operating in serie.

- Height – flow (H-Q).

- Power – flow (P-Q).

- Efficiency – flow (h-Q).

- Characteristic curves operating in parallel.

- Height – flow (H-Q).

- Power – flow (P-Q).

- Suction pipe

- Øinternal = 45,2 mm

- Øexternal = 50 mm

- Drive pipe

- Øinternal = 34 mm

- Øexternal = 40 mm

- Capacity: 250 l

- Electronic pressure transducer –1 a 7 bar // -10.33 to 70 m wc.

- Electronic pressure transducer -1 a 4 bar // –10,33 to 40 m wc. (x3)

- Maximum manometric height 24 m wc

- Flow: 20 / 120 l/min

- Manometric height: 23 / 12 m wc

- Consumed power 0,55 kW (0,75 HP)

- Motor speed 2900 rpm (50 Hz)

- Flow meter

- 5Kg Load cell

- Power consumption of the pumps reading

- 2 Frecuency inverters

- Computerized system with data acquisition system with software (PC with touch screen included and integrated in the structure of the equipment)

- Power supply: 230V/50Hz.