IQ 02.1 – Cyclone Separation

Cyclones are widely used equipment in the industry that allows the separation by centrifugal force of solid particles that are suspended in a gas. They are simple equipments whose operation is based on the separation of the particles by means of the centrifugal force, and that without having movable parts they have a very simple maintenance. As inconvenience we can emphasize that they are not flexible to the changes of concentration, flow or size of the particles.

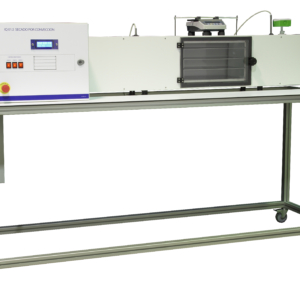

With this IQ 02.1 centrifugal separation equipment, it is intended to study how cyclones, which are gas cleaning devices with particles, remove these from the gas stream.