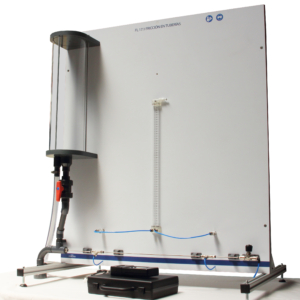

FLB 23.1 – Flow Meter Demonstration

The aim of this training unit is the study and comparison of some of the different types of existing flow meters. This equipment is intended for groundwork and it is implemented with the most didactic and widely-used flow meters.

Description

In our case, the flow meters chosen are a venturi, a rotameter and a diaphragm placed in series will allow direct comparison of results.

Through the realization of some of the practices of this team has failed to understand the behavior of fluids against certain laws of statics, dynamics, thermodynamics. They may implement general principles such as the conservation of mass, or energy in a simplified and easily.

Besides regulating valve with variable flow rates allow you to work according to the needs of the practice.

The pattern of the flow measurements are made using the volumetric tank of the hydraulic bench (required), so that the relationship between the pressure drop and the fluid velocity is also studied.

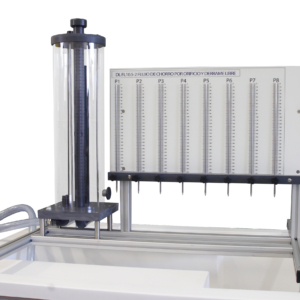

Pressure readings are displayed on a multi-tube manometer 8 outlets through which values are extracted on 8 strategic points of the equipment.

Learning Objectives

- Calibration of flow measuring elements from a flow pattern:

- Rotameter

- Venturi tube

- Diaphragm

- Comparison between the flow rate using the following elements:

- Rotameter

- Venturi tube

- Diaphragm

- Calculating the secondary load loss of the following elements:

- Rotameter

- Venturi tube

- Diaphragm

Technical Data

Bores:

- Øinternal main pipe = 32 mm. ; Øexternal = 40 mm.

Manometer:

- Water column gauge, measuring range 440 mm ca 8 gauge jacks.

Diaphragm:

- Diameter orifice plate Ø20 mm.

Rotameter:

- Measuring range 150-1500l / h

Venturi tube:

- Ø15 mm diameter throat.

- Ø32 mm diameter upstream.

- 21st upstream taper.

- 14th downstream taper.

Requirements

- Hydraulic bench FL 01.4, FL 01.5 ó FL 01.6