EN 05.1 – Hydroelectric Plant with Pelton Turbine

This training unit is composed of: a Pelton turbine, a water tank with a pump, a battery, a regulator, a current converter, a choice of charges both for DC and AC, a control panel, as well as voltage and current meters in key points in the installation circuit. Therefore, the unit enables students to observe and interpret accurately how a hydropower plants operates.

This trainig unit simulates the operation of a power generator, taking into account the hydraulic head of a reservoir, whereby potential water kinetic energy is transformed into electricity thanks to the operation of a turbine.

Additionally, the turbine is equipped with devices for measuring the motor torque and the rotational speed which enables calculations on mechanical energy retrieved and the mechanical and electric power efficiency rate.

Finally, there is a digital pressure transducer at the turbine inlet and a flowmeter which enable the calculation of hydropower output.

- Turbine characteristic curves:

- Torque – rotation speed (M-n).

- Brake power – rotation speed (Pe- n).

- Efficiency – rotation speed (h – n).

- Torque – U (M-U).

- Brake power – U (Pe- U).

- Efficiency – U (h– U).

- Study of the operation of a hydraulic power installation.

- Operation with different types of loads in continuous.

- Conversion of direct current to alternating current.

- Operation with different types of loads in alternation.

- Instalation efficiency.

- Determination of the electrical generation characteristics of the turbine, depending on the rotation speed.

- Curve Intensity – Voltage.

- Short circuit current.

- Open circuit tension.

- Power curve – Voltage.

- Power curve – charge resistance.

- Maximum power generated.

- Form factor.

- Efficiency.

- Tipe: Pelton

- Number of blades: 16.

- Impeller diameter 124 mm.

- Blade depth 14 mm.

- Jet diameter 10 mm.

- Shaft diameter 16 mm.

- Nominal speed 1,900 r.p.m.

- Transparent front to display the impeller in operation.

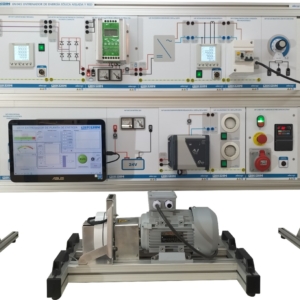

- The equipment is supplied on an aluminium structure, with deposit and pump, in which the necessary flow for the turbine is generated.

- Pressure transducer.

- RPM detection sensor.

- Load cell for measuring torque.

- Electronic control module with two displays to show the system data.

- Battery charge regulator: Regulator with operation at 12 or 24V DC, and maximum current = 10A. Maximum input voltage = 45V.

- Battery: 12V 12Ah battery.

- Sinusoidal inverter operating on Island of 200 VA of power, with single-phase output.

- Analogue ammeter with positive and negative measurement (zero centered) and digital 4-digit with 12-bit resolution + sign.

- Panel of direct current lamps.

- Panel of alternating current lamps.

- Rheostat.

- The equipment is supplied with a complet practice notebook (solved and unsolved).

- The system can be connected to a computer by USB, to register all the data directly in tables.

- Power supply: 230V/50Hz.