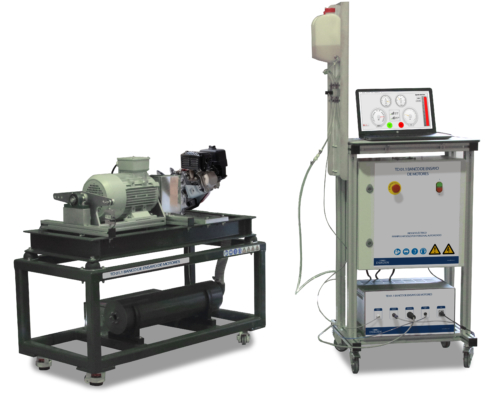

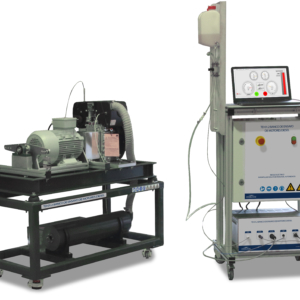

TD 01.1 – Internal Combustion Engine Bench

The TD 01.1 equipment, has been designed for the study and understanding of the behavior of a gasoline four-stroke combustion engine.

The internal combustion engine bench, has two engines, the engine to be tested, and therefore acts as such, in our case a four-stroke gasoline engine, and the braking system, which is constituted by a three-phase asynchronous engine controlled by a frequency inverter. The latter can function as both engine and generator.

COMPUTERIZED SYSTEM:

The Engine Test Bench (TD 01.1) is equipped with a complete computer system, which greatly streamlines the work of tests or practices.

The system is able to control and register all the variables of the equipment.

The tests can be done manually or automatically, just indicate the required variables and indicate how many points we want the graph of results. This way you do not waste time in aiming results and drawing the graphs by hand.

- Torque – Rotational speed.

- Brake power – Rotational speed.

- Temperature – Rotational speed.

- Air/fuel relation – Rotational speed.

- Specific fuel consume – Rotational speed.

- Steel structure with damping system.

- Wheels for easy moving of the unit and blocking.

- Load cell for mechanical torque measurement.

- Exhaust gases temperature sensor.

- Electronic sensor of revolutions measurement.

- Flowmeter for air consumption.

- Digital meter for fuel consumption.

- Air inlet temperature sensor.

- 4-stroke gasoline combustion engine.

- Maximum rotational speed 3.600 r.p.m.

- Maximum power 4,0 KW at 3600 r.p.m.

- Maximum torque 10,8 Nm at 2500 r.p.m.

- Valves at the head.

- Displacement: 163 cc

- Cooling system: forced air

- 15 kg Dry mass.

- Type: Three-phase asynchronous motor.

- Power / Voltage: 7,5 HP / 380 V.

- Brake resistance 3,5 KW, 55 Ohm.

- Computer included.

- Power supply: III 380-415 Vca / 50-60Hz