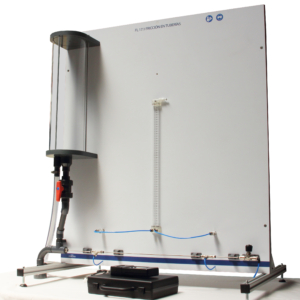

In the case of the centrifugal pump its operation is based on the input of the fluid through the center of the impeller, which has blades for conducting the fluid, and as a result of the centrifugal force is driven outwards. There it is collected by the pump casing, which by the outline its shape leads it to the outlet pipes or to the next impeller.

With this equipment is intended to study the characteristics of a pump running individually at different speeds of rotation. This is possible thanks to the frequency inverter that incorporates which modifies the working speed of the pump according to the case study.

In addition, the flow regulating valve manages to operate the pump at different points of operation, which we experimentally obtain its working curves. These work curves can be compared with those supplied by the manufacturer, as well as those obtained by mathematical calculation.

The flow measurements are carried out by means of the volumetric deposit of the hydraulic bench (required), with which the relationship between the loss of load and the speed of the fluid is also studied.