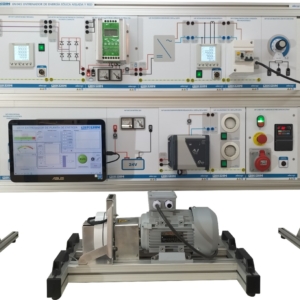

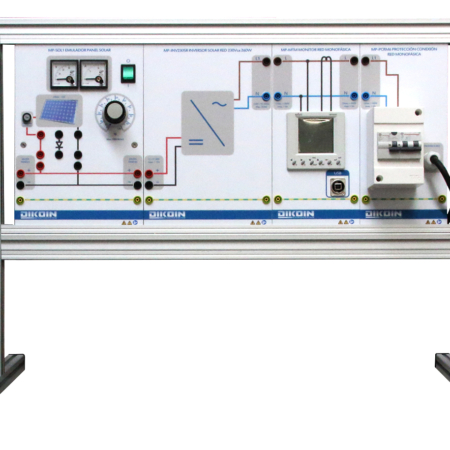

EN 04.1 – Windmill Test-Bench

The Windmill Test-bench (EN 04.1), is a wind tunnel of 2 meters length designed to work with windmills of less or equal to 630mm diameter. The equipment has a 612 mm windmill included, which has a torque and rotation speed measurement system.

The wind tunnel has a transparent part, so a complete sight of the windmill working is allowed. That part, can also be opened, to facilitate the access and manipulation of the system.

The tunnel has a built-in system for the measurement of the speed of the air by means of electronic pressure transducers, to monitor in real time the speed of the air that the windmill is put under.

The new system also has an electronic control of the pitch, to be modified from the control panel or from the computer.

All the system, is monitored and controlled through a control module, which also can be connected to a computer with a USB port.

- Automatic calibration system.

- Wind speed control.

- Windmill brake control with PID.

- Atomatic experiments varying the required parameter by the user autonomously, and recording data at each point.

- The resuslt can be shown in graphs and tables at the software, printed or exported to Excel.

- It only needs a computer with a USB port and windows 7 or better.

- Manual or automatic tests can be done, where the following values can be controlled and registered:

- Wind speed.

- Turn speed of the turbine.

- Torque of the turbine.

- etc.

- Measurement of the power taken by the windmill.

- Determination of the characteristic curves of the power recovered by the windmill based on the wind speed.

- Determination of the coefficient of power of the windmill.

- Determination of the coefficient of power based on the specific speed.

- Obtaining of the coefficient of power based on the angle of pitch of the profile.

- Interchange of the blades of the windmill, for analysis of the variations based on the aerofoil profile.

- Modification of the pitch to see differences.

- Approximate length of the tunnel: 2 meters.

- Maximum diameter of the windmill: 630mm.

- Wind speed in the tunnel, adjustable from 0 to 12m/s.

- Structure made of light weight anodized aluminum.

- Vertically adjustable Legs for a correct level of the equipment.

- Wheels for easy displacement of the equipment, 2 of them with brake.

- Transparent polycarbonate part in the tunnel, with opening for access to the windmill.

- Diameter of the rotor: 612mm.

- Electronic sensor for measurement of rotation speed.

- Load sensor for measurement of mechanical torque.

- The pitch of the blades can be changed.

- Possibility of modification of the picth from the control module or software.

- The blades can be replaced for different ones with 4 screws, without disassembling the windmill.

- Security system that avoids the fan to start if the defense is open.

- Protective grate in the suction bell, that avoids the frontal access (not shown).

- Protective grate in the exit of air.

- Emergency stop.

- LCD display showing: brake power %, wind speed %, pitch %, turn speed of the windmill (rpm), wind speed (m/s) and mechanical torque in the windmill (Nm).

- Potentiometer regulating the pitch of the wind turbine.

- Potentiometer regulating the braking of the wind turbine.

- Potentiometer regulating the air velocity in the tunnel.

- Switch on or off the wind turbine braking system.

- Control selector from control module, or from PC.

- Input: 230V/50Hz. (Others available, please ask).

NOTE: The software is optional. PC not included.