TH 04.2 – Autonomous Electric Brake Francis Turbine

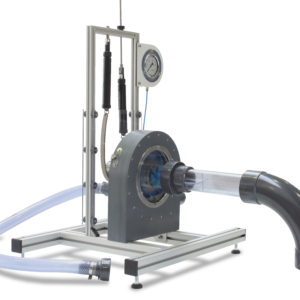

The TH 04.2 model is an advanced, scaled-down Francis turbine (or reaction turbine) simulator, specifically designed to facilitate detailed study and real-time visualization of the behavior and dynamic properties of such turbines.

It features a transparent casing, an innovation that allows for direct observation of how water flow drives the rotor. This visibility extends to the movement of the distributor’s guide vanes, crucial for precise regulation of incoming water flow, providing a unique and comprehensive educational experience.

It includes an adjustable valve for controlling the water inlet flow, offering the flexibility to operate with different water volumes according to experimental requirements.

Its braking system, powered electrically, allows for adjustments in revolutions per minute, enabling experiments with various workloads.

The equipment is distinguished by its full computerization. This means critical variables such as inlet pressure, flow rate, braking torque, and others are monitored and displayed in real-time through a computer integrated into the device, facilitating precise and efficient data interpretation.

Thanks to its comprehensive design, which includes a water tank, pump, and all necessary instruments mounted on a mobile laboratory cart, the TH 04.2 turbine allows for entirely autonomous operation, optimizing practical learning in educational environments.

- Turbine characteristic curves:

- Torque – speed (M-n).

- Brake power – speed (Pe- n).

- Performance – speed (h – n).

- Torque – U (M-U).

- Brake power – U (Pe- U).

- Performance – U (h– U).

- Iso-performance curves.

- Performance set, turbine-electric generator.

- Studying and obtaining the characteristic curves of a centrifugal pump*.

- Obtaining the total return of a central pumping.

- Electric brake.

- Type: Francis

- Material impeller: Polyamide.

- Wheel diameter: 80 mm.

- Number of fixed blades 10.

- Number of guide vanes 6 (adjustable from 0 to 100%).

- Power: 100 W

- Rated speed: 3000 rpm

- The equipment is supplied on an anodized aluminum frame with tank (130 l) and pump in which the required flow for the turbine is generated.

- Pressure transducer.

- Direct detection sensor rpm.

- Load cell for measuring the torque.

- Data acquisition module.

- Computer with software.

- Power supply: 230V / 50 Hz.

- *For pump caracterization, an optional ancillary is required.